- Homepage

- /

- Guide to metering valves: applications, advantages, and types

Guide to metering valves: applications, advantages, and types

Metering valves are crucial for industries that require precise control of fluid flow, whether for dispensing, dosing, or mixing liquids and gases. These valves ensure accurate flow rate management, critical in applications ranging from health tech to agriculture. This article explores the fundamentals of metering valves, their operational benefits, and the specific types developed by Dolphin Fluidics that enhance industrial processes:

- Definition of metering valve

- Working principle

- Applications

- Advantages of metering valves

- Metering valves offered by Dolphin Fluidics

- The impact of metering valves across industries

What is a metering valve?

Metering valves are designed to provide precise control over the flow of fluids. They can adjust the flow to very fine levels, making them ideal for applications requiring exact volumetric regulation. Typically used in analytical and research settings, these valves are also prevalent in industrial environments where precision is key.

Working principle

The operation of metering valves involves a fine-tuning mechanism that allows for the gradual adjustment of fluid flow. This can be achieved through various means such as proportional valves or on/off valves designs, which precisely control the opening through which the fluid passes, thus regulating the flow rate according to the requirements of the application.

Applications of metering valves

Metering valves are essential across a wide spectrum of industries due to their ability to manage fluid dynamics with high precision and reliability. By enabling precise control over the volume and rate of fluid flow, these valves are integral to processes in health tech, food and beverage, agriculture, and industrial sectors. Here, we explore how metering valves are applied within these fields to enhance efficiency, ensure quality, and meet the stringent requirements of diverse operational environments:

Health Tech

In medical devices, metering valves are used to administer precise doses of medicines or to handle critical fluids in diagnostic equipment.

Food and Beverage

These valves ensure accurate measurements and mixtures of ingredients, crucial in maintaining consistency and quality in food production.

Agriculture

Metering valves control the delivery of water and nutrients in irrigation systems, optimizing resource use and enhancing crop yields.

Industrial

In manufacturing processes, these valves play a critical role in the accurate mixing of materials, ensuring product consistency and quality.

If you need more information about which metering valve is most suitable for your industry, contact our team

Contact us for further information

Advantages of metering valves

Metering valves offer several advantages, including:

- High Precision: They provide exact control over fluid flow, essential in many industrial applications.

- Efficiency: By delivering precise amounts of fluid, these valves reduce waste and increase process efficiency.

- Adaptability: Metering valves can be used with a wide range of fluids, from gases to liquids, adapting to various industrial needs.

- Customization: Many metering valves can be tailored to specific applications, enhancing their effectiveness in particular systems.

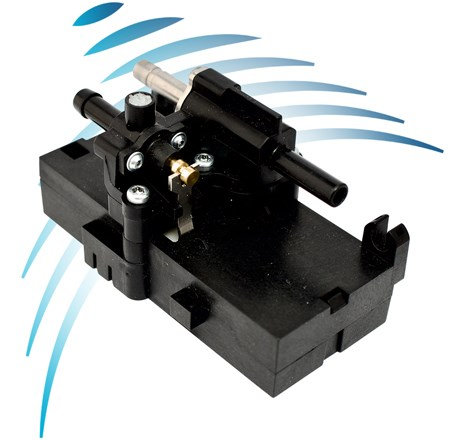

Types of Dolphin Metering Valves

On/Off Valve

Overview

Dolphin Fluidics' On/Off valves are 2-way medium-separated, normally closed valves designed for dispensing and mixing. Characterized by their efficiency and compact design, these valves are optimal for applications demanding high cleanliness and precise flow control.

Advantages

- Lightweight and compact, offering significant space and weight advantages.

- Low power consumption and noiseless operation, enhancing system efficiency and user comfort.

- Patented design with NSF/FDA material compliance, suitable for health tech and food & beverage industries.

Single Channel Valves

Overview

These are digital, 2-way, full-separation smart valves with on/off and proportional closed-loop control, ideal for dosing or dispensing fluids accurately.

Advantages

- Provide accurate dosing without drift, crucial for consistent application performance.

- Customizable to meet stringent functional requirements, ensuring reliability across various industrial applications.

Dual Channel Valves

Overview

Dolphin Fluidics' dual-channel valves feature two independently controlled channels, making them perfect for tasks requiring the simultaneous handling of different fluids.

Advantages

- Allows for compact system design by reducing space, weight, and wiring requirements.

- Digital controls facilitate easy integration with IoT systems for enhanced data management and remote diagnostics.

Digisense valve

Overview

The Digisense Valve from Dolphin Fluidics is a state-of-the-art solution designed for precision fluid management. This dual-channel valve incorporates integrated temperature probes and flowmeters within each channel, enabling highly accurate fluid regulation and dosing. Its architecture supports precise mixing of two different liquids by controlling the outlet temperature, making it ideal for applications that require exact fluid properties. The Digisense is an all-in-one unit that does not require external components for operation, simplifying system integration and enhancing reliability.

Advantages

- Features two independent channels with built-in temperature and flow monitoring for closed-loop control.

- Facilitates precise fluid mixing and dosing with different viscosities.

- Operates with very low power consumption, significantly lower than traditional valves, and silently.

- Offers customization options to meet specific electronic and mechanical interface requirements of various applications.

Digimed valve

Overview

The Digimed Valve is tailored specifically for the healthcare sector, ensuring all materials used meet the ISO10993 standards necessary for medical applications. This dual-channel valve allows for independent proportional control of liquids, air, or gas, providing flexibility and precision necessary for medical devices. Like the Digisense, it integrates easily with external sensors for accurate fluid dynamic control and supports closed-loop operations.

Advantages

- Dual-channel design allows for separate control of air, gas, and liquids, suitable for diverse healthcare applications.

- Ensures safe use in medical environments with all materials conforming to ISO10993.

- Low energy consumption and silent functionality enhance its suitability for sensitive medical settings.

- Customizable interface options to accommodate specific requirements for medical device integration.

The impact of metering valves across industries

Metering valves are indispensable tools in industries requiring high precision in fluid control. Dolphin Fluidics offers a range of metering valves that cater to diverse industrial needs, ensuring efficiency, reliability, and precision. By understanding the specific advantages and applications of these valves, industries can significantly enhance their processes and product quality.

If you need more information about which metering valve is most suitable for your industry, contact our team

Contact us for further informationContact request

Thank you for your interest Error processing your request. Please retry or contact us.

)