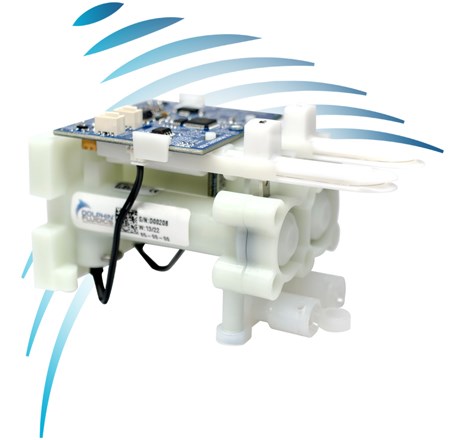

A new series of full-separation single and dual channels proportional valves capable of dispensing liquids with different consistencies and carbonization with extreme precision.

Any food, beverage or ice cream product can be prepared using our integrated valves. Our products are developed and engineered based on customer requests and demands for seamless integration into OEM platforms.

All materials used are NSF and FDA certified.

On this page:

Food industry valves

At Dolphin Fluidics, we understand the critical role that valves play in the food industry. Our valves are specifically engineered to meet the stringent hygiene and safety standards required in food processing. They are designed to handle various food products, including liquid, creamy, and viscous substances. With their precise control and reliable performance, our food industry valves contribute to the smooth and efficient operation of food processing lines.

Key features of food industry valves:

- Hygienic design: Our food industry valves are constructed using materials that are food-grade and compliant with industry regulations. They feature smooth surfaces, crevice-free designs, and easy disassembly for thorough cleaning and sterilization.

- Product integrity: The valves ensure minimal product contamination or leakage, maintaining the quality and integrity of food products throughout the delivery process.

- Precise control: Our valves offer accurate flow control in closed loop, enabling precise dosing, mixing, and blending of ingredients during food delivery.

- High durability: Designed for heavy-duty applications, our food industry valves are built to withstand frequent cleaning, sterilization, and harsh operating conditions, ensuring long-lasting performance.

Do you want to know more about our proportional valves for the Food&Beverage industry?

Contact us for further information

Beverage valves

When it comes to the beverage industry, Dolphin Fluidics provides a wide range of valves tailored to meet the unique demands of this sector. Our beverage valves offer reliable control and exceptional performance for various beverages, including carbonated drinks, juices, coffee, and more. These valves contribute to maintaining the quality, taste, and consistency of beverages during delivery.

Key features of beverage valves:

- Cleanability: Our beverage valves feature smooth surfaces and removable components, allowing easy cleaning and sanitation. They are designed to prevent the buildup of residue and maintain the hygienic standards required in beverage processing.

- Carbonation control: Our valves offer precise control over carbonation levels, ensuring consistent and desired carbonation in carbonated beverages.

- Gentle handling: The valves are designed to handle beverages delicately, minimizing shear forces and preserving the sensory characteristics of the products.

- Beverage-specific designs: We offer specialized valves for different beverage types, such as valves with low oxygen permeability for preserving the freshness of sensitive beverages like wine and beer.

All the applications of our food industry valves

Our food industry valves are designed to streamline critical processes across the food and beverage sector, ensuring precision, efficiency, and reliability. As a matter of fact, we provide smart valves essential in optimizing various operational stages:

- Processing: our food valves are capable of enhancing the production phase by maintaining precise flow control and temperature stability, critical for consistency and product quality.

- Packaging: our products play a pivotal role in preserving product freshness during automated packaging operations;

- Storage: valves that prevent contamination and ensure the integrity of liquid and semi-liquid products are a must-have if you plan on storing edible products;

- Transport: we can offer you valves that guarantee leak-proof performance and compliance with strict safety standards, even in a delicate step such as transporting.

FDA compliant valves for maximum security

Hygiene and safety are paramount in the food and beverage industry, and Dolphin Fluidics takes compliance very seriously.

Our food industry valves are engineered to meet and exceed stringent regulatory requirements, offering peace of mind to businesses that demand excellence. Each valve adheres fully to FDA regulations, ensuring they are safe for direct contact with food and beverages.

In addition to FDA compliance, our solutions are manufactured using materials and designs that promote easy cleaning and sterilization, helping to maintain a contaminant-free environment throughout your processes.

When it comes to safety, there are no gambles to be made: with Dolphin Fluidics, you’re not just investing in technology but in a commitment to total safety, aligned with the strictest industry standards.

Enjoy a perfect cappuccino

Enjoy a perfect cappuccino

Contact request

Thank you for your interest Error processing your request. Please retry or contact us.

)